Background

As the demand for sustainable energy storage solutions increases with the growth of portable electronics and electric vehicles, the need for enhanced energy storage systems becomes critical. To meet these demands, it is crucial to develop rechargeable batteries with enhanced performance, safety, and longevity.

Lithium-ion batteries are a promising solution due to their high energy density and efficiency. However, traditional anode materials, such as graphite, are limited by their relatively low capacity and stability under strenuous cycling conditions. Thus, it is crucial to develop advanced anode materials to balance electrochemical activity and structural stability.

Typically, high electrochemical activity materials often degrade quickly, reducing battery lifespan and posing safety risks. Conversely, materials with greater structural stability usually lack the necessary electrochemical properties for high-performance cycling. Additionally, the manufacturing processes for these advanced materials can be complex and expensive, limiting their practical application.

These challenges highlight the necessity for innovative materials that can simultaneously deliver exceptional electrochemical activity and structural integrity. Achieving this balance is crucial for the large-scale production of advanced energy storage systems, which are vital for the future of portable electronics and electric vehicles.

Technology overview

This technology highlights the fabrication of advanced multilayer composite foil anodes for rechargeable batteries. These innovative foils are engineered with layers that vary in electrochemical activity, where some layers are highly reactive, and others provide robust structural support. This configuration significantly enhances the overall performance and durability of the foil material.

Unlike traditional single-layer anode materials that struggle with trade-offs between reactivity and durability, the composite foil's distinct layers offer a more balanced and effective solution. The active layers optimize battery performance by facilitating superior interaction with lithium, while the structural layers ensure mechanical stability and longevity. These advanced materials enhance the overall efficiency and lifespan of lithium-ion batteries, making this technology an invaluable asset for next-generation energy storage solutions.

By offering a cutting-edge approach that combines high performance with enhanced durability, this technology is poised to meet the growing demands of the energy storage market, from consumer electronics to electric vehicles.

Benefits

- These novel multilayered anodes enhance battery lifespan and safety by combining high electrochemical activity with structural integrity.

- This method of multilayered anode fabrication approach can be utilized with various metals, offering versatility in battery design and optimization.

Applications

- Lithium-ion battery manufacturing

- All-solid-state battery (ASSB) manufacturing

- Electric vehicle manufacturing

- Electronics manufacturing

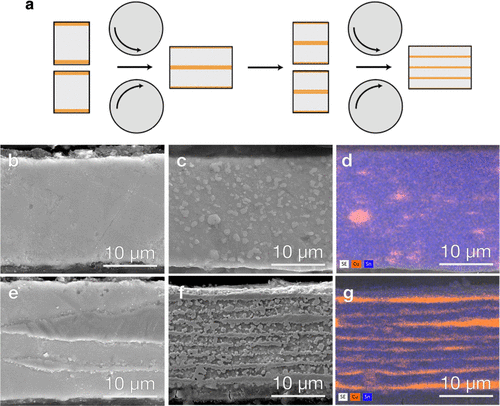

Figure 1. (a) Schematic depicting the ARB process, (b) SEM micrograph depicting an elemental tin foil, (c) SEM micrograph depicting a pewter foil, (d) EDX map overlayed upon a secondary electron image displaying the distribution of copper and tin within the pewter foil, (e) SEM micrograph depicting a nonuniform Sn/Cu multilayered composite foil, (f) SEM micrograph depicting a pewter/copper NCF, and (g) EDX map overlayed upon a secondary electron image displaying the distribution of copper and tin within the pewter/copper NCF. Tin is shown as blue, and copper is shown as orange in the elemental EDX maps.

Publication

Brian T. Heligman, Kevin P. Scanlan, Arumugam Manthiram, “Nanostructured Composite Foils Produced Via Accumulative Roll Bonding as Lithium-Ion Battery Anodes,” ACS Appl. Mater. Interfaces, 14, 9, 11408–11414 (2022) https://doi.org/10.1021/acsami.1c23529

Opportunity

- This multilayer composite foil technology addresses critical challenges in anode material performance, offering a balanced solution that enhances both reactivity and durability.

- By significantly improving battery efficiency and lifespan, this technology is ideal for next-generation energy storage applications.

- This technology is available for exclusive licensing, presenting a unique opportunity to gain a competitive edge in the energy storage market by adopting this advanced anode material technology.

- US Pat. App. No. 17/629,726, “Multilayered Anode and Associated Methods and Systems,” available for exclusive license.