Background

Rare earth elements (REEs), such as lanthanides, yttrium, and scandium, are critical components in numerous advanced technologies, including electronics, energy storage systems, and medicine. Currently, the majority of REEs are sourced from a limited number of mining operations, which poses substantial risks to geopolitical tensions, supply chain disruptions, and environmental concerns. Moreover, REE mining operations require high energy consumption, produce significant greenhouse gas emissions, and negatively impact local ecosystems. For the sustainable development of advanced technology, it is crucial to develop alternative methods of REE extraction. Notably, coal combustion for energy production generates large quantities of coal fly ash, a byproduct that is often treated as waste and disposed of in landfills. This fly ash contains REE concentrations up to 1500 ppm, presenting a largely untapped resource that could alleviate the dependency on conventional mining.

Technology overview

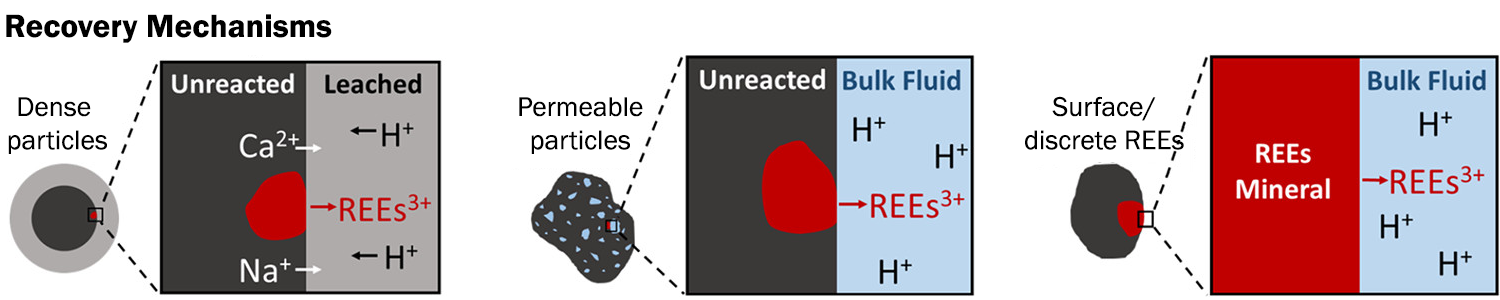

Researchers at The University of Texas at Austin have invented a novel spatiochemical characterization method for optimizing rare earth metal extraction from coal fly ash. This method was demonstrated in aluminosilicate matrices of fly ash samples (collected from Powder River Basin feed coal), revealing the influence of ash’s microscale physical properties on REE recovery. For example, REE recovery in dense aluminosilicates is controlled by progressive leaching. Alternatively, intraparticle pore fluid flow controls REE recovery in porous aluminosilicates. Impressively, this technology utilizes both processes to optimize REE recovery in any ash waste.

Publication: “From Ashes to Riches: Microscale Phenomena Controlling Rare Earths Recovery from Coal Fly Ash” (https://doi.org/10.1021/acs.est.2c04201)

Benefits

- This cutting-edge method extracts REEs from coal fly ash using advanced spatiochemical characterization techniques

- Provides the ability to achieve high (> 60%) minerals recovery effectiveness, with fast kinetics, using mild leaching reagents that are environmentally benign.

- The method can be applied to various ash wastes, offering versatility and optimized REE recovery.

- Reduce dependency on geopolitically sensitive REE sources, enhancing supply chain stability and security.

Applications

Electronics manufacturing; lithium-ion battery manufacturing; coal ash recycling

Opportunity

- Over 100 million tons of coal fly ash are still produced every year in the United States. There is an opportunity to transform this ash into a valuable source of REEs, reducing waste and promoting resource sustainability.

- Pending PCT patent application PCT/US2023/031024, will enter the national phase by February 21, 2025, and is available for exclusive license