Background

Dr. Alex Q. Huang has developed a new power semiconductor technology, a Conductivity Controlled Bipolar Transistor (CCBT), with primary application in power electronic converters. Dr. Huang is the Dula D. Cockrell Centennial Chair in Engineering at the Department of Electrical and Computer Engineering and a professor at The University of Texas at Austin, with primary research interests in power semiconductor technologies, advanced power electronics, smart grid and renewable energy integration, and power management integrated circuits. He has published over 550 journal and conference papers and is credited with more than 20 U.S. patents. His research has broad applicability in energy storage applications, the rapidly developing field of advanced materials development, and electrical energy conversion technologies.

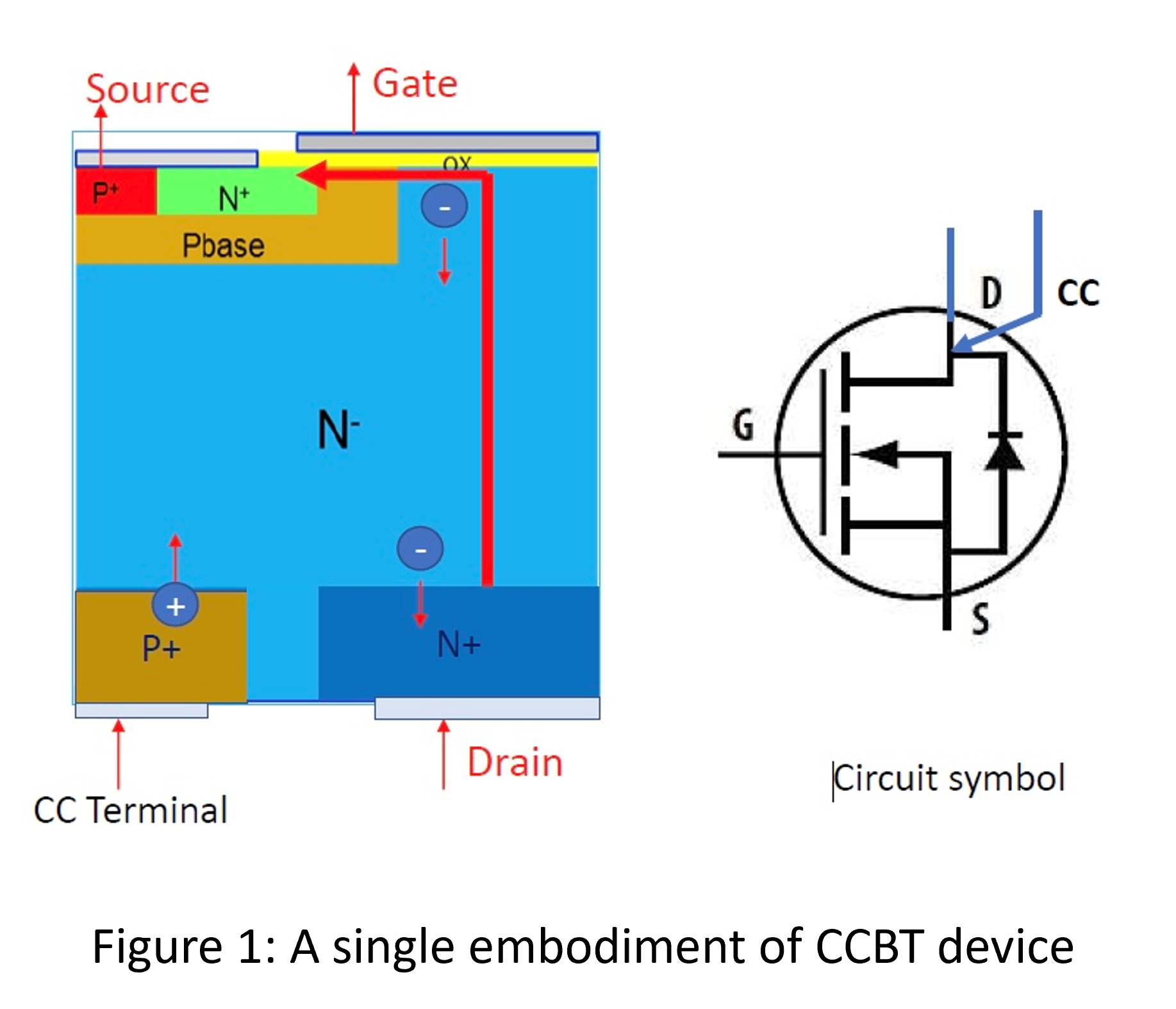

Technology description

The developed CCBT device has been designed in six different configurations to improve upon the performance of state-of-the-art semiconductor power devices (e.g., transistors, switches, rectifiers), including MOSFET, BJT, and IGBT designs. Energy improvements are realized by modifying power device design/construction to add a P+ layer for use as an electrode/CC terminal and an N+ layer which is added in proximity to the P+ layer for use as a functioning drain/collector contact. The use of the developed CCBT technology allows for the construction of semiconductor devices fabricated in either four-terminal or three-terminal designs with the P+ and N+ layers added to either the top or the bottom of a power cell. CCBT device construction is viable using a variety of wide bandgap materials (e.g., Si, SiC, GaN, others) to increase the device’s capability to breakdown voltages of up to 50kV with < 1V forward drop and decreases in power losses as compared to conventional IGBT devices.

A CC drive simulation was performed using a P+ layer electrode as the CC terminal and an N+ layer electrode as an anode, which resulted in a conductivity improvement of up to 1000X compared to background doping of 1e14. A 600V CCBT (e.g., CC-MOSFET) simulation was conducted, which realized loss improvements ranging from 35% to 52.5% (e.g., energy savings accounting for only conduction) compared to an IGBT design. The developed CCBT system shows significant potential for use in a range of developing technologies, including electric vehicle drives, motor drives, and various renewable energy power generation/conversion systems.