Background/unmet need

Activated carbon fiber (ACF) is a material with high surface area and a nano-porous structure, giving it many unique properties. It has been used for making novel yarn, woven, knit, and non-woven textiles. Although these products exhibit excellent performance in many consumer end-uses such as water/air purification, chemical solvent adsorption and recovery, biochemical protective garments, and energy storage, their market growth is limited. This setback is mainly due to two major barriers: high cost and lack of manufacturing infrastructure. A scalable, low-cost method of ACF manufacturing would allow proliferation of ACF into various markets worldwide.

Invention description

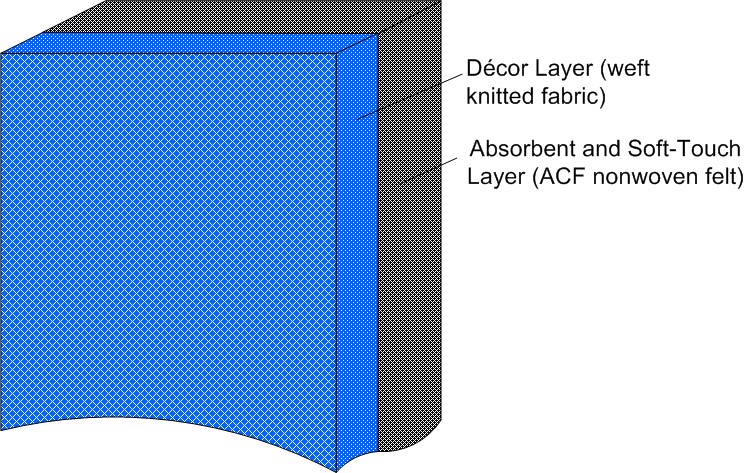

Researchers at The University of Texas at Austin have developed a method to produce multi-functional transportation interior fabrics utilizing ACF that are noise-absorbing across a range of high and low frequencies, odor-absorbing, flame-resistant, and electrically conductive. The combination of these functions makes the developed fabric materials competitive for interiors of next-generation aircraft, vehicles, and trains. As shown in Figure 1, the ACF non-woven felt can be used with a decorative surface layer to provide an aesthetically pleasing product.

Figure 1. Schematic of ACF non-woven felt with a décor surface layer for decorative purposes. The underlying ACF non-woven felt layer absorbs odor and dampens noise to provide a more pleasant experience for passengers on aircrafts, road vehicles, or trains.

Features and benefits

- Lightweight, which is important in an aircraft application

- Flame-resistant and heat insulating

- Low emission of smoke and toxic gas

- Highly noise-absorbent for quiet flights or vehicle rides

- Highly odor-absorbent

- Low-cost production

- Easily scalable manufacturing process

Markets/applications

Aircraft manufacturers (new aircraft); airlines (retrofitting existing aircraft)