An invention that allows for more precision and automation with less operator intervention, limiting the variability from batch to batch in the large-scale coffee bean roasting process

Background

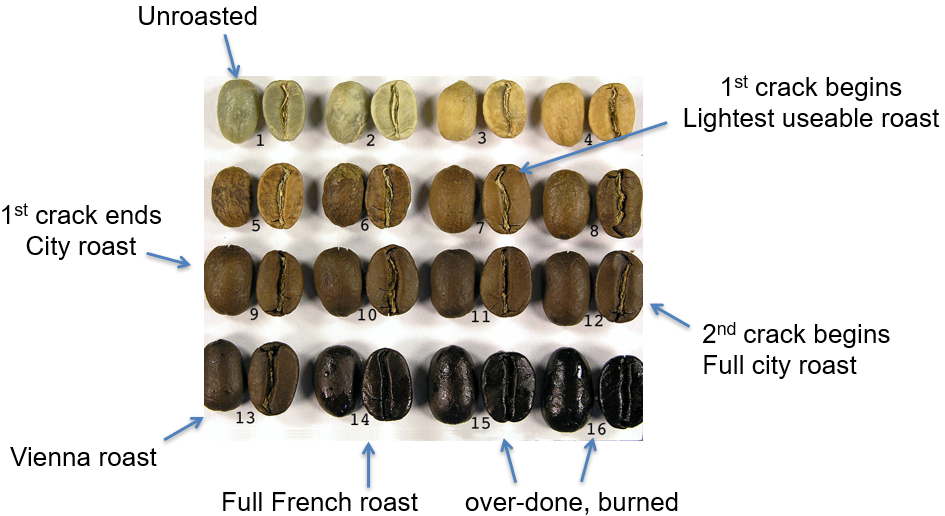

Coffee is an essential commodity that has a $30 billion-dollar annual market. The energy required to roast the necessary coffee beans to supply this demand costs about $1 billion dollars. Optimizing the roasting process can realize substantial cost reduction in the energy required for roasting coffee beans. Coffee beans must be roasted before they are used in any form of coffee beverage. The amount of roasting required for a given coffee bean depends on the desired type of end-product coffee beverage, as shown in Figure 1. Time and temperature are the primary parameters that can be controlled in the roasting process, both of which determine the color, flavor, and aroma of the final coffee beverage.

Description

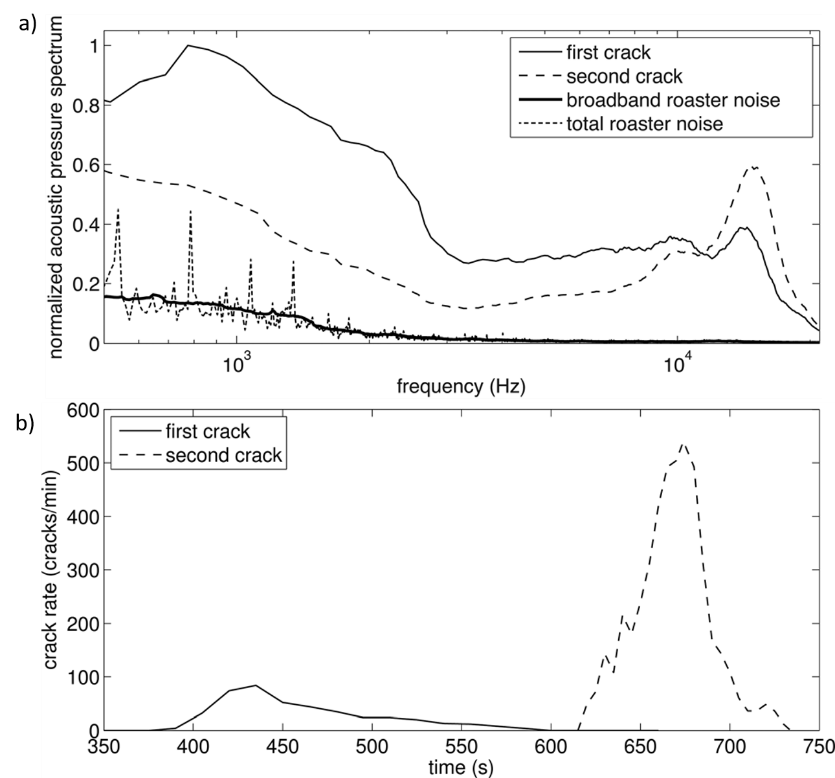

Acoustic indication of a first crack and a second crack of the coffee beans gives a prime indication for where the coffee beans are in the roasting process. Currently, coffee roasting on the industrial scale is monitored by a human operator. However, with the large level of background noise in an industrial factory, it can be hard for the manual operator to hear the first or second crack and stop the roasting process at the desired stage. This shortcoming of the current methodology introduces undesired variability in the final roasted batches.

Researchers at The University of Texas at Austin have developed a new methodology that removes a large degree of manual operation in the determination of the roasting stage by implementing acoustic sensors and an algorithm which can monitor the roasting process in real time. The unique sound signature and crack rate between the first and second crack—as shown in Figure 2a and 2b, respectively—serve as the primary acoustic signatures picked up by the sensors and fed into the algorithm, which identifies these sounds over typical factory background noise to provide critical information on the current stage of the roasting process.

Figure 1. The anatomy of coffee bean roasting. Coffee beans shown at various stages of roasting.

Figure 2. a) Acoustic pressure spectrum of coffee roaster during roasting process. b) Crack rate of coffee beans during coffee roasting process.