Problem statement

Lost circulation can have disastrous consequences including blowout (uncontrolled kicks) and loss of life, so close monitoring to quickly assess and control such events is essential. Market estimates indicate that over $2 billion USD is spent annually to combat and mitigate these events. Real-time measurement of mass flow is critical to obtaining improved estimations of delta flow rate, a primary indicator of kicks or mud-loss. This information is particularly desirable at the well inlet, where pressures can approach 7500psi. Most available technologies can determine either flow or density. The few currently viable technologies that can determine both, either do not perform well in high pressure conditions or have other issues like the need for a radioactive source.

Technology description

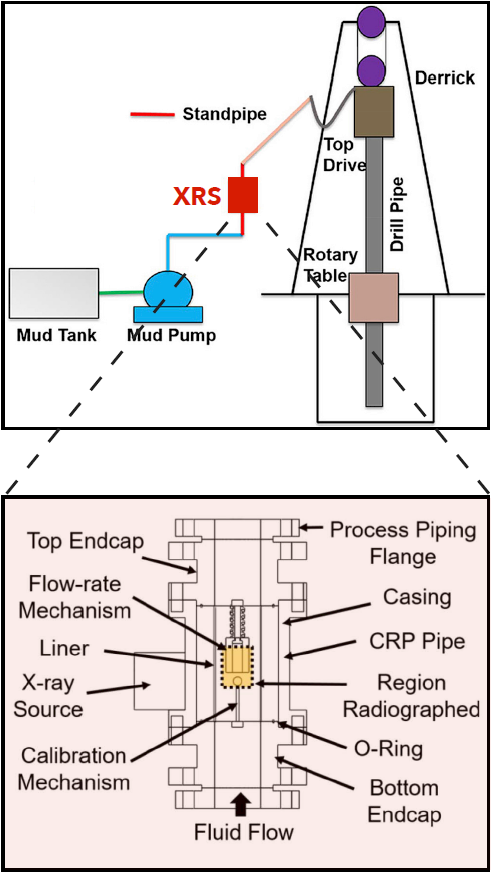

Researchers at The University of Texas at Austin provide an advanced non-radioactive, X-ray based sensor technology (XRS; see Fig. 1) that allows real-time (RT) diagnosis of problem events, so that preventative measures can be taken before well collapse or excessive mud loss. Using low-cost polychromatic X-ray sources that do not require linear accelerators, they show that highly accurate density measurements can be made with standard Beer-Lambert approximations.

In order to further improve the accuracy, beam hardening effects are mitigated by using a filter to preharden the beam. Using these and other important modifications, they demonstrate that such an instrument is feasible and offers considerable merit over the currently available technologies for high-pressure conditions.

Stage of development and results

Both lab and a field prototype were built. The prototypes (see Figure) were tested in the laboratory using an empirical and a model-based method, to measure changes in mud density. Temperature, pressure variations and aeration levels in the mud pits were accounted for by implementation of appropriate correction factors to the laboratory-generated look-up tables. Both these methods were tested on two different mud systems and both yielded greater than 99% accuracy at 1 Hz measurement frequency.

These data indicate that no existing sensors used for similar applications can match the measurement accuracy and frequency that may be offered by this technology. Commercial development of this sensor would greatly improve the safe drilling of complex wells with narrow drilling windows.

IP Position: Published PCT application WO2019199590A1

Benefits

- Works in high pressure conditions with greater than 99% accuracy

- Low cost

- Does not require a monochromatic x-ray source or linear accelerators

- Does not require a radioactive source

Fig. 1: Blow-up schematic of the XRS device