Background

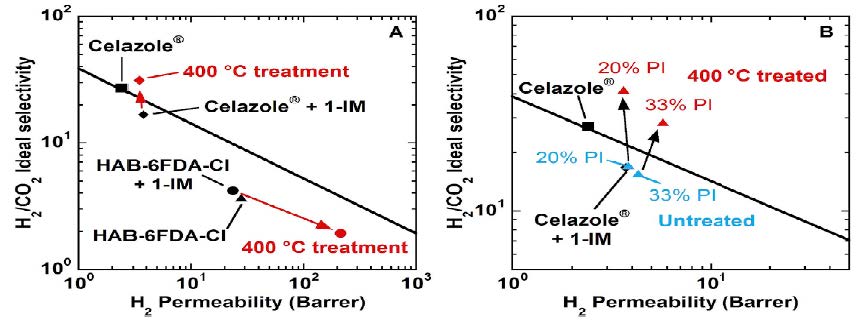

Polybenzimidazoles (PBIs) have been studied for use as gas separation membranes for aggressive, high-temperature applications such as hydrogen separations due to their high chemical and thermal stability. Increasing the permeability of PBIs while maintaining good selectivity for gas pairs such as H2/CO2 would make such technology competitive for pre-combustion carbon capture applications and for emerging applications such as H2/CH4 and H2/hydrocarbon separations. Polymer membranes typically exhibit a so-called “upper bound” tradeoff, where increases in permeability are almost always accompanied by decreases in selectivity, which makes it challenging to find materials that show improvement in both properties and which exceed the “upper bound”.

Technology description

Researchers at The University of Texas at Austin have developed a composition and method to improve the permeabilities and/or selectivities of PBIs by, for example, blending ortho-functionalized polyimides with rigid, aromatic polymers such as polybenzimidazoles, followed by a thermal treatment—resulting in thermally-stable membrane materials with gas separation properties that exceed the current H2/CO2 separation upper bound.

Benefits

Using the composition and method membrane:

- Throughput was enhanced up to 5X, which would result in decreased membrane module and compressor cost

- Membrane H2/CO2 selectivity is preserved, or in some cases, even enhanced

- Membranes are easy to fabricate and can utilize existing commercial materials, making them more cost-effective than other strategies to improve membrane permeabilities.

More details about this technology may be found in this peer-reviewed journal article.

H2/CO2 upper bound for HAB-6FDA-CI and Celazole® (A) pure polymers cast with 1-methylimidazole (1-IM) with and without heat treatment at 400°C and (B) 20/80 and 33/67 wt% blends compatibilized with 1-IM with and without heat treatment at 400°C. All measurements were performed at 35°C and 10 atm. Solid lines represent the 2008 upper bound.