A new easy to use universal pavement deflection monitoring system to monitor road health

The deflection of pavement when a moving vehicle passes over it is an important measure of its condition. Since pavement damage is initially not visible on a road’s surface, pavement deflection should be measured as often as possible for the efficient maintenance of drivable roads. When damage is severe enough to become visible, the pavement must be completely replaced, which is much more expensive than repairing it when the damage initially occurs. Current pavement deflection sensors are limited in their capabilities; either they require slow movement for measurement, which can heavily disrupt traffic, or they do not universally work on all type of pavement.

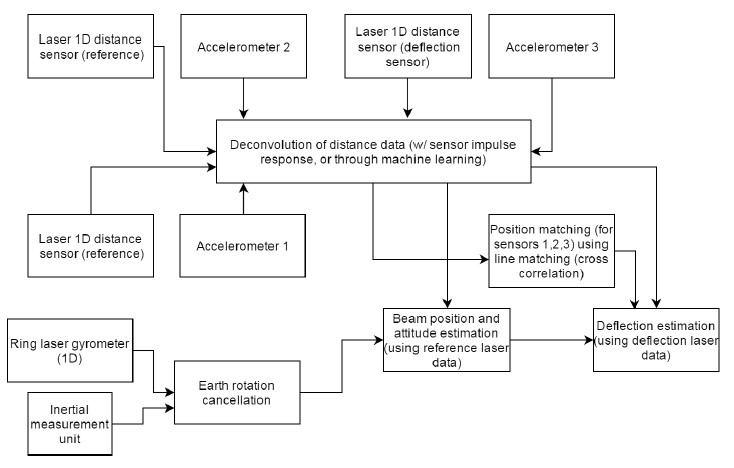

Researchers at The University of Texas at Austin have developed a new pavement deflection measuring system that does not require the vehicle it is mounted on to move at slow speeds and universally works on all types of pavements. The system is summarized in Figure 1 and can be easily mounted on a truck for use. Multiple laser scanning sensors, in conjunction with high-precision accelerometers and gyrometers, generate a very accurate reading of pavement deflection on a moving platform, having a 10-micrometer tolerance of measurement. Unlike other systems, this system can measure pavement deflection even when moving at high speeds, which allows pavements to be scanned by a moving vehicle without disrupting traffic. Other systems with similar capabilities in terms of measurement speed only work on certain types of pavement; this system works universally on all types of pavement.

Fig. 1: Overview of new pavement deflection measurement and monitoring system.