A sustainable material with properties suitable for food packaging

Background

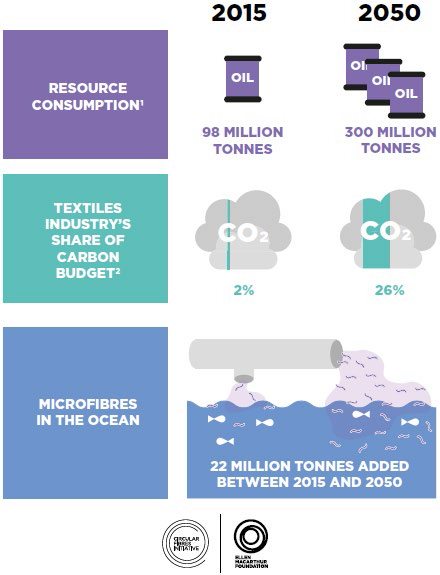

Typical polymer food packaging materials are good barriers to air, but not moisture. In contrast, metallic food packaging materials block air and moisture, but are opaque and do not allow for vision of the packaged food. Cellulose nanofiber films typically fall into the category of polymer films that are not good at blocking moisture. Cellulose nanofibers have many industrial uses; however, current methods for producing them are net negative in their environmental impact, and that negative impact is set to drastically increase over the next three decades. Finding ways to recycle materials and develop sustainable practices is of the utmost importance to reduce the environmental impact of textile processing.

Technology description

University of Texas at Austin researchers have developed a process for producing cellulose nanofibers from a sustainable source. This new method developed by Prof. Chen reduces the environmental impact of producing cellulose nanofiber films that block air and moisture diffusion, making them ideal for food packing. Traditional processes require raw wood which then undergoes a pulping process that is energy- and cost-intensive. This new technology allows for recycled cotton to be the starting cellulose source for producing cellulose nanofiber films that are ideal as barrier films for blocking the diffusion of oxygen and moisture. Films produced with this sustainable method are clear, strong, nontoxic, printable, and thermally stable. This method and the properties of the resulting films are ideal for the food packaging market.