Background

Pipeline infrastructure in oil and gas, water systems, and chemical processing requires regular internal inspections to detect corrosion, blockages, and structural damage. However, many pipelines are narrow, tortuous, and operate under variable pressure and flow conditions, making access with conventional tools difficult. Rigid robotic crawlers often cannot maneuver through diameter transitions or tight bends, while manual inspections are dangerous or impossible in confined, fluid-filled environments. There is growing demand for compact, self-guided robots that can navigate complex pipe geometries, maintain traction on slick surfaces, and capture high-resolution imaging without disrupting operations or requiring elaborate setup.

Most existing in-pipe inspection tools lack the adaptability or traction needed to navigate wet, irregular, or variable-diameter conduits. Many solutions require tethering or anchoring, further complicating deployment in real-world pipelines. These limitations hinder inspection and maintenance of critical infrastructure, particularly in small-diameter or dynamic flow environments.

Technology overview

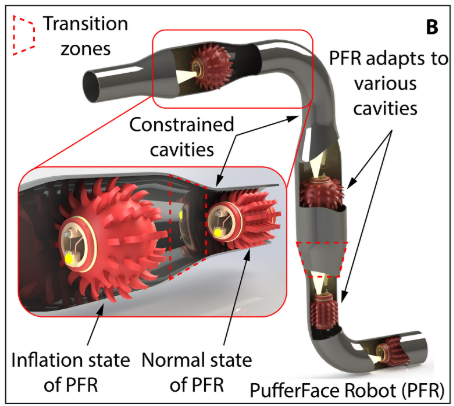

The PufferFace Robot (PFR) is a miniature, untethered inspection robot engineered for centimeter-scale pipeline navigation. Measuring just 15 mm in diameter and 30 mm in length, the robot integrates a hollow cylindrical body containing a micro camera, onboard LED, eccentric-mass DC motor, and internal air channels. Wrapped in a 1mm-thick Dragon Skin silicone shell patterned with flexible spikes, the robot expands via internal pressurization to conform tightly to pipe walls up to 1.5 times its resting diameter.

Locomotion is achieved through three operational modes: vibration-only (for straight sections), pressurization-only (for size adaptation), and a combined mode in which inflation enhances contact and deflation synchronizes with motor-induced vibrations for forward motion. This hybrid strategy generates normal forces sufficient to propel the robot with forces 20 to 35 times its own weight. ABAQUS-based simulations confirm the robot’s ability to maneuver through elbows, T-junctions, and diameter shifts. The embedded camera and lighting system allow real-time inspection during motion, making the robot ideal for autonomous operation in fluid-filled, dark, and geometrically complex pipelines.

Benefits

- Replaces bulky, rigid crawlers with a compact, adaptive robot designed for real-world pipelines

- Provides untethered, real-time inspection in environments where human access is impossible

- Navigates elbows, junctions, and variable-diameter pipes without tethering

- Generates high traction on slippery or inclined surfaces

- Compact form factor for deployment in pipelines <2 cm in diameter

- Integrates onboard camera and lighting for real-time imaging

- Combines inflatable skin with motor vibration for adaptive, forceful locomotion

Applications

- Oil & gas pipeline inspection

- Water infrastructure monitoring

- Chemical processing line maintenance

- Hazardous environment exploration

- Industrial in-pipe robotics

Intellectual property

Provisional patent filed 11/04/2024

Publication

Adaptable cavity exploration: Bioinspired vibration-propelled PufferFace Robot with a morphable body (DOI: 10.1126/sciadv.ads3006)

Opportunity

Available for exclusive licensing